Project Showcase

What does this mean for large construction projects?

Traditionally, a draftsperson or site engineer would be required to take manual measurements to draw-up a design layout which would then be used to determine required materials.

As any project manager would understand too well, these measurements and plans are open to human error often causing issues within the supply chain.

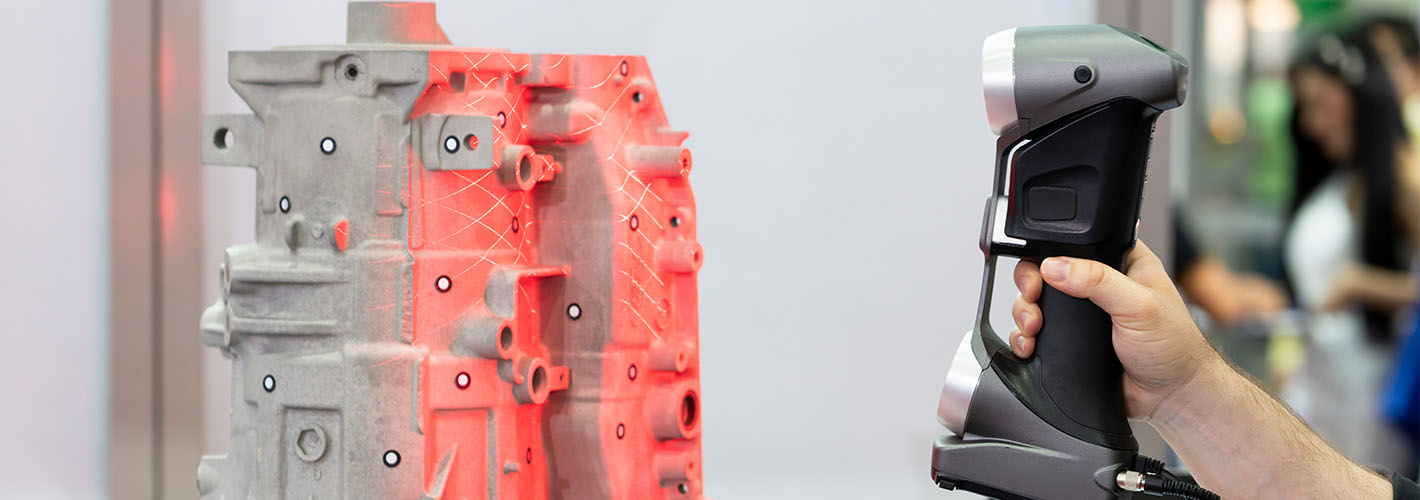

Contemporary steel industry innovators are now able to use advanced scanning and digital imaging technology to take a 3D snapshot of the site. This information is used by a draftsperson who then creates a complete digital representation of the worksite.

The data and information are fed to the new machinery, which cuts and processes a precise amount of material ready for transportation back to the site.

Traditionally, a small mistake in measurement could potentially cause a range of issues:

- Extending completion dates

- Blowing budgets

- Over or underestimating required materials

With new technology and machinery, human error is completely removed from the equation.

Contact BridgeFab for structural steel projects

At BridgeFab we can take care of the structural steel process from start to finish – so contact us today or call on (07) 3373 8777.